Diesel oil dialysis, as the name suggests, has the same principle as the blood filtration system inside the human body. Just as the kidneys keep our fluids clean, filtration systems bypass ensure the vitality of the fuel, preventing unnecessary expenses and reducing the company’s ecological footprint.

Find out more about this process and some symptoms that may indicate that you need to clean the oil in your machines.

What is diesel oil dialysis?

This procedure is, in short, a technique offiltration which removes all diesel oil from inside the tank and separates it from contaminants, such as water and solid or biological particles. These, in turn, may come from the oil degradation process itself (oxidation, degradation of additives), due to wear such as abrasion between the moving parts of the engine or contamination by air.

Diesel oil dialysis gets its name because of the similarity of the process to the filtration system of the human body: just as blood must constantly pass through the kidneys to be purified and maintain the health of the body, oil from a hydraulic system it needs to be constantly being sanitized, and for the same reason.

The diesel oil dialysis process uses a filter system bypass, so titled for not being part of the machine’s integrated filtering system. That is, the dialysis machine is coupled to the oil pump outlet, usually by means of a stainless steel hose, and sucked into the filtration system.

Once inside the device, the oil will pass through a set of membrane filters capable of retaining fine particles. This is an important detail, since coarse particles can be retained by the filtration system that comes with the engine, but not the finer ones. Smaller particles, however, can cause great damage if they reach internal parts of the engine, significantly reducing its useful life, efficiency and increasing the associated operating cost.

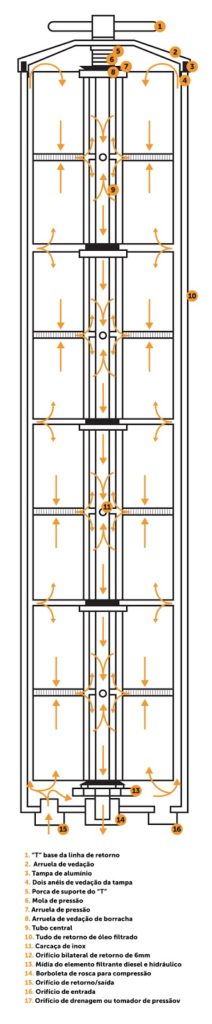

Although the details of the bypass filtering system are patented and, therefore, cannot be disseminated widely, it is possible to know the dynamics of operation of these filters in the following illustration.

Why should I do this on my machines?

The main advantage of performing diesel oil dialysis on your engines is that, after such an operation, there will be less wear on the engine, since the finer particles of contaminants will be trapped in the filter membranes. In addition, oil life will be extended.

It can thus be said that, with the help of cleaning carried out by diesel oil dialysis, wear particles and impurities in the oil are removed, but without removing important additives. Characteristic oil values, such as Viscosity Index, oxidation, nitration and sulfation, are also not changed with the application of dialysis filtration. In this sense, only harmful particles will be extracted, while the overall integrity of the oil’s properties is maintained after filtering.

Diesel oil dialysis filtration systems are recommended, in particular, for transportation companies with large fleets, public transportation services with a significant fleet of buses, companies in the forestry or agricultural sector, among others.

What are the benefits of periodically diesel dialysis?

It is recommended to carry out such a filtering process whenever you are unsure as to the source of the fuel oil from which your machines will be filled. Before they merge, the engines show signs of problems that you can preventively solve. Among the diesel oil contamination symptoms to watch out for are:

- Engine failures

- Decreased power

- Increased fuel consumption

- Reduction in Rotations per Minute (RPM)

- Smoke

- Failures to start

- Engine cycle or reduced speed failures

- Engine noise

- Neutral failures

In all of these cases, diesel dialysis can reduce or totally eliminate the source of the problem, that is, oil contamination. For this reason, the recommendation to carry out periodic fuel filtering, particularly in the case of transport or agricultural companies that have large fleets, as mentioned in the previous topic.

The reason for this is that the engines of these machines have a large volume of oil circulating constantly during the operational process. For this reason, cleaning the oils, and their consequent reuse, will significantly reduce maintenance costs, in addition to expanding the durability of equipment and the useful life of the fuel. Another advantage is that maintaining the quality of the oil allows it to operate in optimal conditions, reducing the environmental impact and the company’s ecological footprint.

Periodic oil analyzes should be carried out to ensure that the fuel supply will not cause damage to the engines in order to reduce their useful life and work capacity. Any compromise in the operation of the engines, in this case, can also cause significant losses to the production process. The loss of power of a cane harvester, for example, can impair the flow of work in the field and consequently the production of alcohol, conditioned to a minimum supply of vegetable matter for its proper functioning.

Therefore, diesel oil dialysis must be included as a routine practice to ensure the useful life and health of its fleets. Just like the kidneys for human blood, an oil system bypass acts as a dirt remover that is potentially harmful to the engine.

The engine, before presenting significant failures, shows signs of contamination, which must be carefully observed and evaluated by the maintenance managers. In this sense, diesel oil dialysis is a predictive maintenance technique that helps to prevent costs caused by unforeseen failures in the production process.

Make one now price from POC Filters and find out how diesel oil dialysis contributes enormously to cutting your maintenance costs.