Biodiesel in diesel

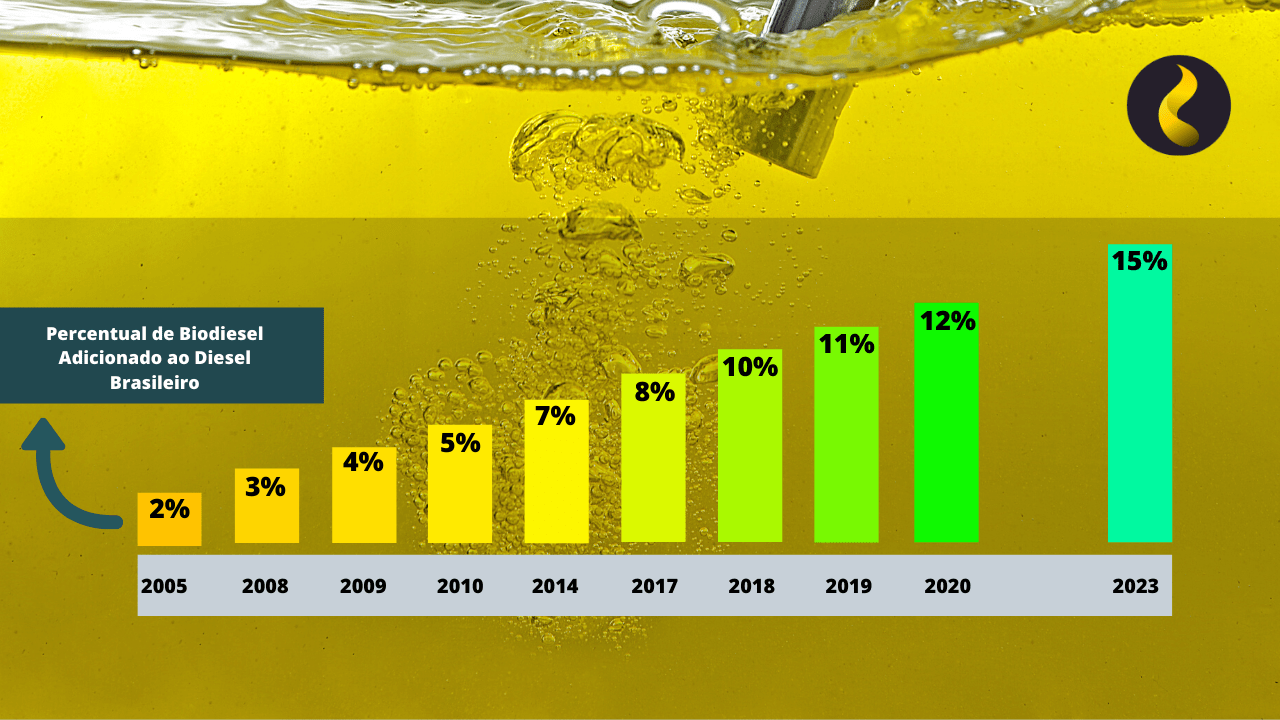

As seen in recent years, the growth of the biodiesel mixture in diesel has become increasingly common in Brazil. And, according to industry experts, the gradual increase in the percentage is already provided for by law.

To give you an idea, in March 2020, the National Agency of Petroleum, Natural Gas and Biofuels (ANP) announced that the biodiesel mixture in diesel increased from 11% to 12%. The decision was made after tests proved the safety of the increase.

However, it should be noted that the volume of the addition, approved by the ANP, is up to 15% in diesel sold to the final consumer.

Percentage evolution will continue to increase

See the evolution of the percentage of biodiesel in diesel from 2005 to the projection for 2023.

According to resolution 16, of 2018, the increase in the mixture of biodiesel in diesel will be gradual until the year 2023, when it will reach up to 15%. That is, in 2021, for example, the percentage goes from the current 12% to 13%.

According to resolution 16, of 2018, the increase in the mixture of biodiesel in diesel will be gradual until the year 2023, when it will reach up to 15%. That is, in 2021, for example, the percentage goes from the current 12% to 13%.

Brazil imports around 80 million barrels of diesel annually. Thus, explain POC Filters professionals, the increase in the mixture of biodiesel in diesel is here to stay. See here, other data about Biodiesel.

What does increasing the mixture mean?

When reading about increasing the blend of biodiesel in diesel, you may even ask yourself: but, what does this mean for you or your company? Well, it can mean a lot!

As with diesel oil, bacteria in biodiesel can also be present, but with an aggravating factor. As biodiesel has less sulfur in its composition (which is good for the environment), the appearance of water is greater, which favors the appearance of bacteria.

It is worth noting that contamination by bacteria is extremely harmful, if not eliminated. It causes, for example, the reduction of the useful life of the engines. This is because the bacteria in biodiesel contribute to damage important parts of the gear, such as nozzles and injection pumps.

Thus, the deterioration generates an increase in the cost of maintenance, which becomes more frequent. Bacteria in biodiesel still cause:

-

Deterioration of oil;

-

Oxidation of nozzles, pumps and injection engines;

-

Need for constant filter change due to saturation;

-

Engine and machine failures;

-

It makes the machines or vehicles stand still, which generates the loss of money;

-

Reduced service life of bearings and other parts;

-

Increased consumption;

* Important to know

The presence of bacteria in biodiesel can also be characterized by a bad smell, faults or sudden shutdown of the machine or vehicle, as well as “rough” operation.

Understand how bacteria appear in biodiesel

Bacteria in biodiesel are caused by the presence of water in the fuel. Water contributes to the formation of microbial contamination. It is important to note that a colony of bacteria can double in size in short periods, such as 20 to 30 minutes.

According to professionals from POC Filters, the presence of water in biodiesel occurs because of 3 different ways:

-

Condensation: this usually occurs through the air entering the tank. Temperature variations cause water condensation to occur;

-

Supply: on some occasions, water may also be present in the fuel, especially when of low quality;

-

Cleaning: inadequate cleaning paves the way for the presence of water in the diesel;

How to combat the problem?

First of all, it should be noted that increasing the biodiesel mixture in diesel will not automatically generate the growth of contamination. However, you need to be aware, because the possibility is very real.

The good thing is that, although the presence of water in biodiesel cannot be avoided, it can be controlled. As water is the cause of the appearance of bacteria in biodiesel, the work needs to be focused precisely on reducing the presence of the liquid.

Among the actions that help to eliminate bacteria from biodiesel are:

-

Ensure the constant evaluation of the monitoring of biodiesel, which detects the presence of impurities;

-

Eliminate bacteria in biodiesel through microfiltration, one of the most efficient processes today and which has great results.

Why does microfiltration give the best results?

In addition to the bacteria present in the water, diesel with biodiesel can be contaminated by small particles, which also contribute a lot to damage parts of machines, equipment and engines.

As is known, the most used process for cleaning lubricating oil is filtration. It turns out that the common filtration process fails to identify and retain all impurities present in the oil (solid or liquid). What to do, then?

Invest in microfiltration. This is because the precision of the process makes it possible to guarantee a much more effective retention. This is because microfiltration is able to retain particles up to 2 microns in size, as well as considerably reducing the presence of water and, consequently, bacteria. But how does oil microfiltration work?

How Microfiltration Works

In this thorough oil filtering process, the fluid is passed through a set of filters capable of completely eliminating contaminating particles, as well as water. Microfiltration is an Australian oil filtration technology, capable of retaining approximately 900 grams of solid contaminants and also removing sludge from the fluid.

Many people do not know, but the new oils are naturally contaminated by the manufacturer. Therefore,it is not only the oil already used that needs to undergo the microfiltration procedure, but the new one as well. Among the advantages of the process are:

-

Less wear: the reduction of contaminants makes the oil circulate with greater purity through the equipment, which reduces damage;

-

Cost reduction: with microfiltration, maintenance costs become much lower;

-

Greater efficiency and availability of the machine: it is common for the lack of care to generate an increase in unscheduled maintenance, which causes significant losses. However, with the machine up to date, a high level of productivity is guaranteed, as well as losses are reduced;

-

Increased service life: with clean oil, parts and components are preserved, which increases service life;

In this way, microfiltration is also the best way to maintain the purity of the oil, even in times of increased biodiesel mixture in diesel.

What is biodiesel?

As the ANP defines itself, “biodiesel is a biodegradable fuel derived from renewable sources that can be produced from animal fats and plant species such as soybeans, palm, sunflower, babassu, peanuts, castor and jatropha”.

In other words, it is different from traditional diesel, which is a fossil fuel, generated through the distillation of oil. In the case of Brazil, around 80% of the biodiesel produced is from soy oil, which even contributes to domestic production.

To be produced, the oil is removed from the plants, mixed with methanol and stimulated by a catalyst, which causes a chemical reaction. Then, the oil is separated from the glycerin and undergoes a filtering process.

However, for biodiesel to be mixed with diesel, it is necessary to comply with the technical specifications determined by the ANP. Thus, it is free to be used in machines, equipment, engines, etc.

Environmental contribution of Biodiesel

<p “>The last decades have been marked by the increase in global warming, which has the contribution of fossil fuels, such as gasoline and diesel, for example.

Because it is of vegetable origin, biodiesel contributes to the environment, being totally sustainable. This is because it reduces the emission of polluting gases, it is not toxic, it is less explosive and, above all, it is renewable.

The mixture of biodiesel in diesel

Brazil is one of the countries that produces the most biodiesel in the world. The mixture of biodiesel in diesel started to be used, optionally, in 2003. In January 2008, the mandatory insertion was set at 2%, soon to 3% (in July of the same year). Since then, it has been rising, as can be seen in the history of the ANP.

Stay in!

Do you want to know more about mixing biodiesel in diesel and how to act to keep the oil clean? Then get in touch with POC Filters professionals, who are always on hand to assist in the search for the best solutions for your equipment, machine or engine!