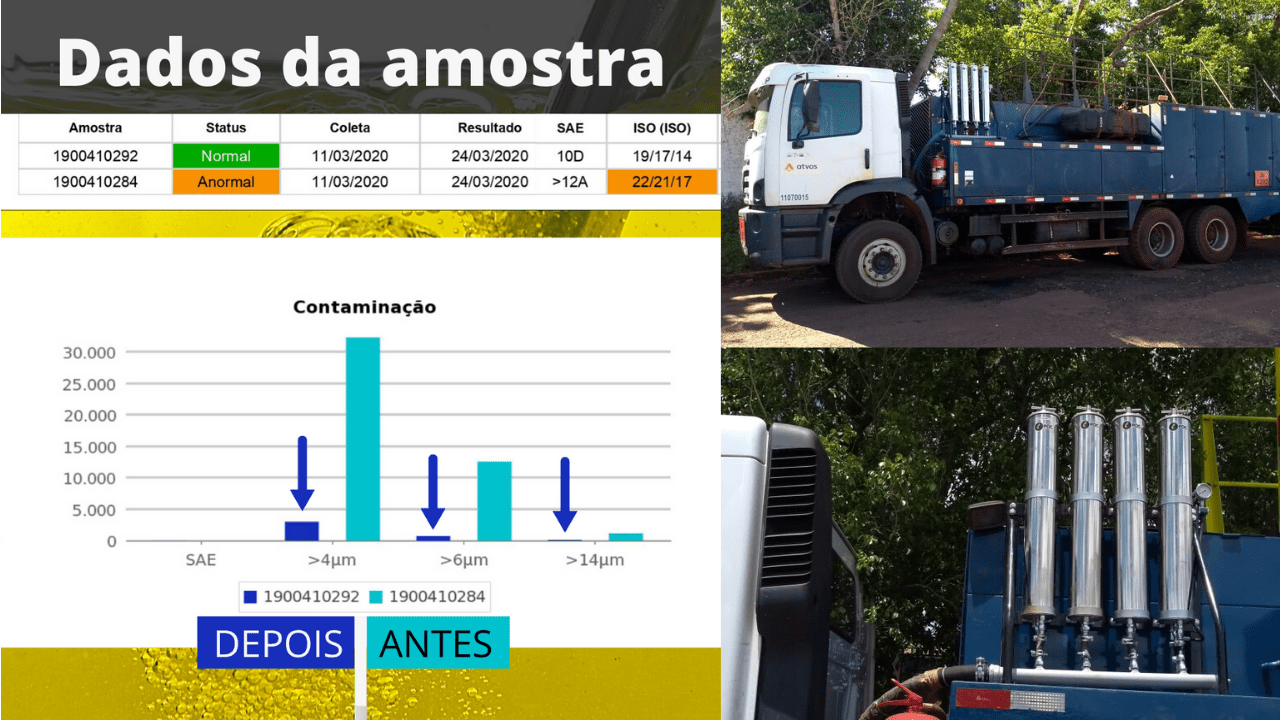

See a case study with the implementation of a Microfiltration System for diesel oil in a Supply Train.

The quality of fuel, especially diesel, has become a crucial factor in achieving the good performance of machines and equipment and productive success. On this journey the Diesel Supply and Lubrication Train popularly known as MELOSA is a strong ally. This mobile unit is also called by other names such as: lubrication and supply train; convoy tank, convoy truck, etc. This equipment is a strategic resource for supplying and maintaining fleets, whether in sugar-alcohol plants, mining units, construction sites, road pavements, in agriculture, or in the handling of cargo and logistics.

Diesel Microfiltration System in a Supply Train

Since modern machines require oils and fluids free from contamination, Microfiltration Systems have been gaining prominence among maintenance professionals, especially predictive maintenance. See in the images a case study carried out at a Sugar-Alcohol Plant in which 19 units / trucks supply trains received diesel oil microfiltration systems.

In one of these units / truck we made a case study with the oil samples taken BEFORE and AFTER the installation of the FMF 404 micro filtration system. The results of the first sample (1900410284 – GREEN) indicated a large amount of microparticles of 4, 6 and 14 microns. The sample (1900410292 – BLUE) removed after the installation of the filtration system revealed a sharp drop in contaminants, especially 4 micron microparticles.

Why install Microfiltration on a supply train truck?

According to the oil analysis data presented above, it would not be an exaggeration to say that a convoy truck without a micro filtration system dumps particles of 4, 6 and 14 microns directly into the tank of machinery and equipment. Somado a isso os filtros primários das máquinas retém apenas partículas maiores que 5 micras e saturam rapidamente. The microparticles that enter combustion systems, or even hydraulic systems, cause breakage and wear of components such as cylinders, pumps and valves, discontinuity in the operations of the machines, internal leaks, accelerated aging of the lubricating oils themselves. All of this contributions to the increase in operating costs due to corrective maintenance stops. Prevention, and the supply of clean fluids is a good reason to install a microfiltration system in a supply train, since about 80% of equipment failures are caused by fluid contamination.

Understand why the customer installed microfiltration systems on trains

“Shutdowns for unscheduled corrective maintenance”, this was the reason. According to the customer, after analyzing the scenario it was noticed that the fuel was already of poor quality from the refinery. As a result, harvesting was interrupted countless times because machines such as harvesters and trucks needed maintenance. In general, the most common problems were: Early saturation of primary filters; Maintenance on nozzles, pumps and injection systems.

Read moreCost of Maintenance x Cost of Machine Downtime

Photo gallery Diesel Microfiltration System in a convoy truck

Austech oil microfiltration systems are modular and can be installed at fixed points or on a supply train.

See other advantages of oil microfiltration in a supply train:

- Prevents premature wear of parts;

- Prevents loss of productivity;

- Reduces consumption;

- Avoid unexpected failures;

- Increases performance;

- Reduces the oxidation of nozzles, pumps and injection engines;

- It reduces the chances of stopped machines;

Oil filtration: cleaning standards

It should be noted that the oil filtration process needs to follow standards that guarantee the cleaning of the fluid. Such standards are regulated by international bodies. Examples are:

To learn more click on the desired Standard and access a special article.

ATTENTION – Transport of dangerous products

Many companies and farms transport fuel and other products using barrels and other containers. Whether due to structural difficulties, lack of information, or “bad faith”, this type of practice is highly dangerous for the environment and for the quality control of inputs. Regarding the quality of the inputs, the fuel transported in a precarious way is subject to contamination such as humidity, dust, which favors the proliferation of fungi and bacteria. This will certainly compromise the performance of machines and equipment. For the environment, improvised fuel transport is extremely harmful, as the risk of leakage can threaten biomes, water sources, harming people who depend on these resources. Whoever transports oils and fuels for fleet maintenance, either by train or in an improvised manner, is subject to the rules established by ANTT (National Land Transport Agency), which regulates the transport of products considered dangerous. To be within the law, it is necessary to meet a series of requirements, both in relation to the vehicle and in terms of the material transported. If you were in doubt as to whether it is within the law, that is, following the correct rules, we leave a link from ANTT on the regulation of the transport of dangerous products. Click and access http://www.antt.gov.br

Conclusion

As we saw throughout the text, the Comboio Truck is an excellent ally for fleet maintenance and supply. However, the lack of a microfiltration system ends up placing large amounts of moisture and solid microparticles inside the tank of machines and equipment that will compromise performance and productive efficiency. As we saw in this case study, the installation of a microfiltration system in the entire fleet of convoy trucks at a Sugar-Alcohol Plant and the supply of contamination-free fuel have generated less downtime and expenses with the maintenance of the productive fleet.